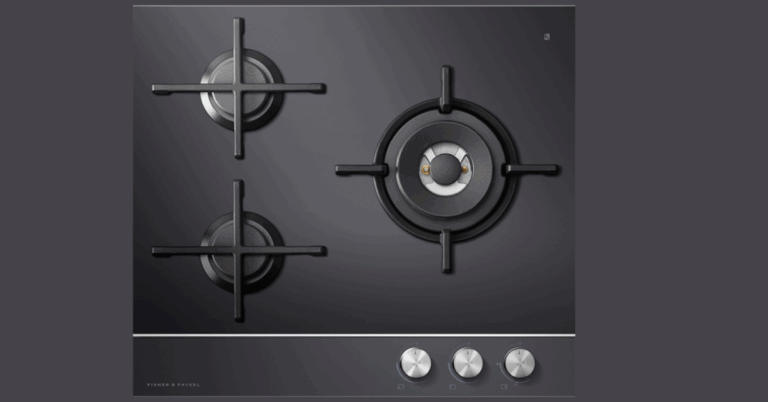

Cruise Cooker 4-Hot Round Stove: A Game Changer for Marine and Cruise Ship Kitchens

Running a galley on a cruise ship or marine vessel presents unique challenges: limited space, fluctuating power supply, strict safety standards, and the need for equipment that’s both durable and efficient. One piece of kitchen gear that has garnered particular attention is the Cruise Cooker 4-Hot Round Stove. Compact yet powerful, this free-standing cooking range with four round hot plates is designed specifically for the demanding environment of cruise ships, marine vessels, and offshore installations.

The Role of the Cruise Cooker 4-Hot Round Stove in Marine Settings

Galley operations aboard cruise ships are like high-wire acts: chefs must prepare large quantities of food in relatively confined spaces, often while the ship is rocking, with periodic power fluctuations, and under strict regulations. In that context, the Cruise Cooker 4-Hot Round Stove offers several advantages:

-

Space efficiency: Its round plate arrangement and compact footprint make the best use of limited galley real estate.

-

Ease of installation: As a free-standing unit (i.e. not built-in), it can be placed where needed without extensive structural modifications.

-

Multi-functionality: Four independent hot plates allow simultaneous cooking of different items (e.g. sauce, sauté, boiling, simmering).

-

Robust construction: Marine-grade materials and finishes are essential for resisting corrosion, high humidity, and constant motion.

-

Power management: The design must accommodate variable electrical loads and ensure stable performance under fluctuating voltages—a common occurrence at sea.

In practice, the Cruise Cooker 4-Hot Round Stove becomes a central piece of galley workflow, enabling chefs to plan multiple cooking tasks in parallel, respond to sudden changes in menu demands, and maintain safety and reliability under marine conditions.

Technical Features to Expect

A high-quality marine cooking range like the Cruise Cooker 4-Hot Round Stove typically offers:

-

Four round hot plates, each possibly with its own control dial (or digital control), allowing independent temperature settings.

-

Heating technology: Could be resistive (electric) or induction, depending on vessel power systems and preferences.

-

Temperature control and stabilization: Given power fluctuations at sea, the stove should manage overshoots and maintain stable heat settings.

-

Sturdy construction: Use of stainless steel, marine-grade metals, and welds that resist vibration and corrosion over long voyages.

-

Safety features: Overheat protection, automatic shutoff, anti-tilt or anchoring provisions, and heat insulation to reduce risk in a moving environment.

-

Ease of cleaning: Smooth surfaces, removable drip pans, sealed controls to guard against salt spray and grease.

-

Ventilation compatibility: Galley ventilation is critical; the stove design should integrate well with exhaust hoods, ducting, and conform to shipboard safety codes.

Because the original product page could not be accessed reliably (the link returned an internal error), I cannot confirm specifics such as dimensions, power ratings, or materials. But these are the design features one would expect in a purpose-built marine cooking unit.

Use Cases and Advantages in Cruise Ship Galley

1. Efficient Menu Execution

With four hot plates, chefs can run several cooking operations simultaneously — for example, boiling a sauce, sautéing vegetables, keeping a soup warm, and searing meat. This flexibility is crucial when serving large numbers of passengers on tight schedules.

2. Backup to Larger Ranges

Even with more substantial ranges aboard, having a robust 4-hot plate stove as a backup or auxiliary unit is extremely useful during peak times, maintenance, or when specialized cooking is needed near other prep areas.

3. Resilience Against Motion and Vibration

Marine environments are harsh: waves, vibrations, and constant movement stress kitchen equipment. The Cruise Cooker must be engineered to remain stable, avoid spillage, and handle the torque and lateral forces experienced on a moving ship.

4. Scalability for Smaller Ships or Modules

Smaller vessels or remote modules (e.g. offshore platforms or expedition ships) may not need large ranges. A compact 4-hot stove meets cooking needs without overwhelming space or power infrastructure.

5. Energy Efficiency and Load Balancing

By enabling selective use of only those plates needed, the stove can reduce total energy draw during lighter cooking periods—helpful when managing limited onboard power. Advanced versions may even offer features like phase balancing or smart load shedding.

Designing Operational Procedures Around the Stove

To get the maximum benefit from a Cruise Cooker 4-Hot Round Stove, galley management should consider:

-

Pre-planning plate usage: Assign certain plates for continuous tasks (e.g. steam, simmer) and rotate others for dynamic cooking.

-

Scheduling maintenance: Marine kitchens require frequent inspections. The stove should be cleaned, calibrated, and checked for wiring and insulation periodically.

-

Power surge protection: Incorporate voltage stabilisers or surge suppression upfront to protect internal heating elements and controls.

-

Crew training: Operators must be aware of the dynamic nature of cooking at sea knowing how to compensate for rolling, pitching, and sudden vessel motions.

-

Spill and catch-tray protocols: Because liquids may slosh, ensuring spill trays and splash guards are in place reduces risk to electronics and wiring below.

-

Safety drills: The galley crew should be practiced at emergency shut-offs, plate isolation, and rapid response in case of electrical faults, fire, or motion events.

Challenges and Considerations

While a 4-hot round stove offers many benefits, a few challenges must be addressed:

-

Power constraints: Large loads on multiple plates can stress shipboard power systems. It’s essential to match stove capacity to available power circuits.

-

Heat dissipation: In cramped galleys, heat management is harder. Adequate ventilation and exhaust capacity are mandatory to prevent overheating.

-

Maintenance access: Marine kitchens often have tight spaces. The stove should allow for easy access behind panels or modular components.

-

Salt environment: Corrosion is a constant enemy. The choice of materials and coatings must resist salt air, spray, and chemical cleaning agents.

-

Vibration fatigue: Over time, constant vibration can loosen fasteners or damage wiring. Marine-grade mounting and regular inspections mitigate this risk.

-

Safety regulations: Shipboard cookers must comply with marine safety codes (SOLAS, IMO, classification societies). It’s essential that manufacturers provide proper certifications and safety documentation.

How the Cruise Cooker 4-Hot Stove Highlights Innovation in Marine Catering

In effect, the Cruise Cooker 4-Hot Round Stove embodies the trend of adapting terrestrial kitchen technology to the harsher realities at sea. Innovations such as:

-

smart temperature feedback controls that adjust settings under voltage fluctuations,

-

modular design for easier repair and replacement,

-

open architecture for integrating with ship automation systems,

-

and materials engineered for long life in corrosive conditions

—these features underscore how modern marine galleys are evolving.

Moreover, the move toward smaller, more flexible cooking modules (instead of massive built-in stoves) reflects an operational philosophy: versatility, redundancy, and resilience. The Cruise Cooker is a prime example of how that philosophy is being actualised.

Sample Layout Scenarios

Here are some ways a cruise ship might integrate the 4-hot round stove into its galley:

-

Central module next to main range: Positioned near the primary cooking line to allow chefs to offload tasks during peak periods.

-

Satellite station: A self-contained unit in a satellite or banquet prep area to reduce cross-traffic in main galley corridors.

-

Portable emergency backup: Mounted on a secure anti-tilt base, this stove can be moved for temporary use during renovation or repair of other equipment.

-

Specialty cooking station: Used for specialty menu items (e.g. breads, sauces, confectionery) separate from bulk cooking lines to reduce interference or heat conflicts.

Each layout requires attention to ventilation, power routing, crew access, and safety zones.

Best Practices for Selection and Deployment

When selecting a marine cooking range like the Cruise Cooker 4-Hot Round Stove, decision-makers should weigh:

-

Power rating & voltage compatibility: Ensure compatibility with ship’s bus voltage (e.g. 440 V, 60 Hz, 3-phase or other vessel standards).

-

Plate wattage and heating range: Evaluate how fast the plates heat and the maximum load required.

-

Material and finish: Seek high-grade stainless steels (316 or better) and passivation to resist corrosion.

-

Certifications: Look for class society approval, marine safety compliance, and documentation.

-

Ease of service: Modular parts, easily replaced heating elements, and access to wiring or control modules.

-

Safety mechanisms: Overheat and overcurrent protections, shutoff valves (if gas hybrid), and fail-safe operation.

-

Weight and anchoring: The unit’s weight and mounting provisions must match the vessel’s structural allowances.

-

Warranty and support: Prefer suppliers with marine experience, global service networks, and spares availability.

Once onboard, installation must be overseen carefully: leveling, secure anchoring, proper electrical grounding, tight cable runs, and integration with galley ventilation systems.

Conclusion

In a cruise ship’s galley, every square meter and every kilowatt matters. The Cruise Cooker 4-Hot Round Stove meets that need by delivering a versatile, compact, and marine-hardened cooking solution. Its four independent round hot plates allow chefs to multitask efficiently, while its design is tailored to withstand the challenges of sea travel movement, corrosion, power fluctuation, and space constraints.

For cruise ship operators and marine culinary planners, integrating such a range into kitchens offers both practical and strategic advantages: improved redundancy, flexibility in workflows, and the ability to meet high standards under constrained conditions. With thoughtful selection, installation, and maintenance, this specialized stove can become a keystone appliance in delivering high-quality meals reliably across the seas.