Ensuring Purity from the Start: The Role of a Paddy Cleaner

In the journey from field to plate, the quality of rice is paramount. While polishing might add the final gleam, the foundation of superior rice lies in the very first step: cleaning. A Paddy Cleaner is the unsung hero of the rice milling process, diligently removing impurities and ensuring that only the purest grains proceed to the subsequent stages. At Ricetec Machinery, we understand that a clean start is crucial, and our paddy cleaners are designed to deliver exceptional purity and efficiency.

The Importance of a Paddy Cleaner: Setting the Stage for Quality

Raw paddy harvested from the fields is far from pristine. It often contains a mixture of unwanted materials, including:

- Dust and Chaff: Fine particles that can affect milling efficiency and rice quality.

- Stones and Pebbles: Hard impurities that can damage milling equipment.

- Straw and Stalks: Larger debris that needs to be removed.

- Immature or Broken Grains: Defective grains that reduce the overall quality and yield.

- Mud Lumps: Clods of soil that can contaminate the rice.

A paddy cleaner’s primary function is to eliminate these impurities, ensuring that the rice entering the milling process is as clean as possible. This has several crucial benefits:

- Protection of Milling Equipment: Removing stones and other hard objects prevents damage to expensive machinery like hullers and polishers, reducing maintenance costs and downtime.

- Improved Milling Efficiency: Clean paddy flows more smoothly through the milling process, leading to higher throughput and reduced energy consumption.

- Enhanced Rice Quality: Removing impurities from the start results in a cleaner, more consistent final product, with improved appearance, taste, and shelf life.

- Reduced Contamination: Eliminating dust, mud, and other contaminants ensures that the rice meets stringent quality standards and is safe for consumption.

- Increased Head Rice Yield: By removing broken and immature grains early on, the paddy cleaner helps to maximize the yield of valuable whole rice.

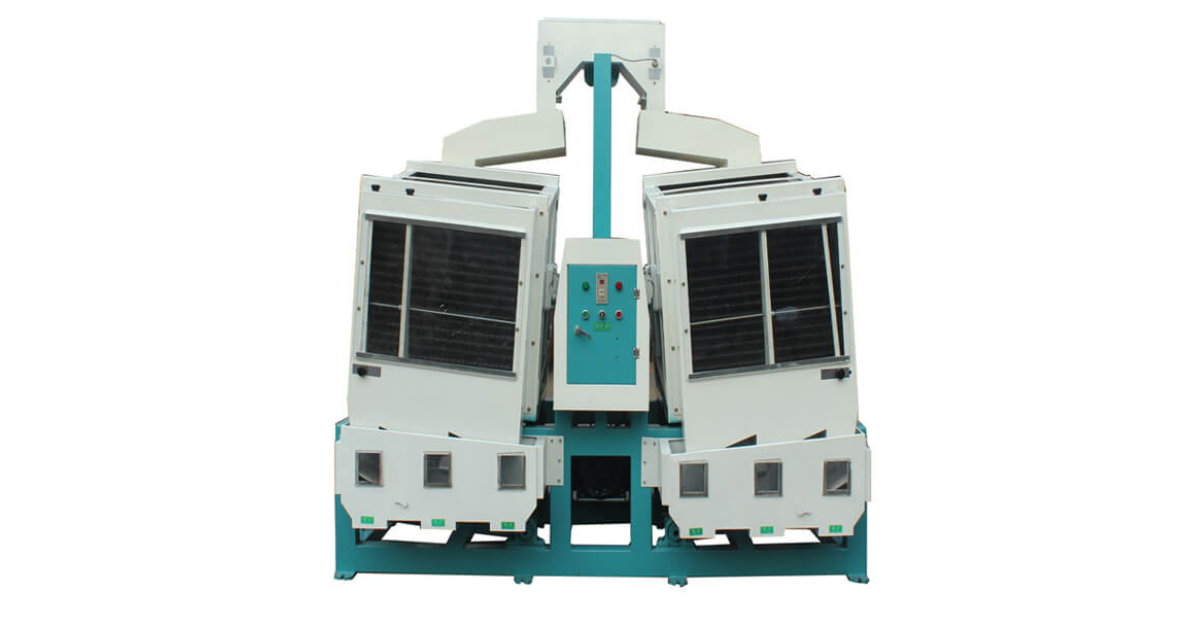

How a Paddy Cleaner Works: A Symphony of Separation

Paddy cleaners employ a combination of techniques to achieve effective separation:

- Feeding and Distribution: Raw paddy is fed into the machine, often using a controlled feeding mechanism to ensure a consistent flow.

- Screening: The paddy passes over a series of vibrating screens with different mesh sizes. These screens separate impurities based on size, removing larger debris like straw and smaller particles like dust.

- Aspiration (Airflow): A powerful blower creates an upward flow of air, which lifts and removes lighter impurities like chaff and dust.

- De-stoning (Gravity Separation): Some paddy cleaners incorporate a de-stoner unit, which uses a vibrating deck and airflow to separate stones and other heavy objects from the paddy based on density.

- Discharge: The cleaned paddy exits the machine, ready for the next stage of processing.

Types of Paddy Cleaners: Tailoring to Specific Needs

Paddy cleaners come in various designs and configurations to suit different requirements:

- Rotary Cleaners: These use a rotating drum with screens to separate impurities.

- Vibratory Cleaners: These employ vibrating screens for efficient separation.

- Combined Cleaners: These machines combine screening, aspiration, and de-stoning functions for comprehensive cleaning.

- Pre-Cleaners: Designed for initial cleaning of raw paddy with high levels of impurities.

- Fine Cleaners: Used for more thorough cleaning after pre-cleaning.

Key Considerations When Choosing a Paddy Cleaner

Selecting the right paddy cleaner is crucial for optimal milling operations. Consider the following factors:

- Capacity: Ensure the machine’s capacity (tons per hour) matches your mill’s throughput.

- Cleaning Efficiency: Look for machines that can effectively remove a wide range of impurities.

- Durability: Choose a machine built with robust materials for long-lasting performance.

- Ease of Operation and Maintenance: User-friendly designs and accessible components are essential.

- Energy Efficiency: Opt for models that minimize power consumption.

- Manufacturer Reputation: Partner with a reputable supplier like Ricetec Machinery for reliable equipment and support.

Ricetec Machinery: Your Partner in Pure Rice Processing

At Ricetec Machinery, we offer a comprehensive range of paddy cleaners designed to meet the diverse needs of modern rice mills. Our machines are engineered for:

- Exceptional Cleaning Efficiency: Ensuring the removal of all types of impurities.

- High Throughput: Maximizing your mill’s processing capacity.

- Reliable Performance: Built with durable components for continuous operation.

- User-Friendly Operation: Simple to use and maintain.

- Energy Efficiency: Reducing operational costs.

Investing in a high-quality paddy cleaner from Ricetec Machinery is an investment in the quality and efficiency of your entire rice milling operation. It’s the first step towards producing rice that meets the highest standards of purity and commands premium prices in the market.